double-suction centrifugal pump|double entry centrifugal pump : sourcing Pressure fluctuation is the primary factor that affects the stability of turbomachines. The goal of the present work is to explore the propagation of pressure fluctuations in a two-stage double-suction centrifugal pump. The pressure fluctuation characteristics of each component of a two-stage double-suction centrifugal pump are simulated under four typical flow rates based .

Discover the ultimate guide to steam (autoclave) sterilization for healthcare professionals. Learn the principles, processes, and critical role in patient care.

{plog:ftitle_list}

Nubyra autoclave - 6 litres - 230v | Price: £2359 | Category: Autoclave | Browse amongst .

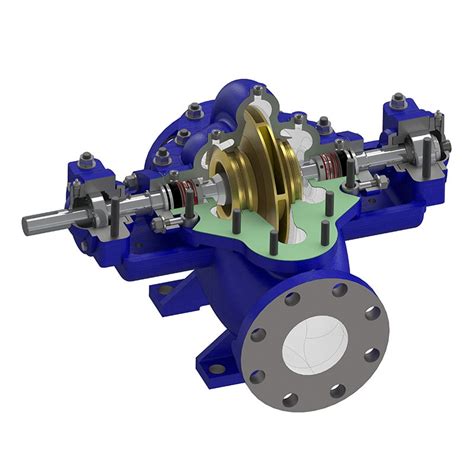

The Bell & Gossett VSX Double-Suction Split-Case Pump has maintenance-free bearings, one . The impeller is a direct part of the pump to do work on the liquid in the pump, and is the energy supply device of the centrifugal pump. The suction port in the center of the pump casing is connected to the suction pipe, which is .The pump is a centrifugal, single stage, double suction type. When properly installed and when given reasonable care and maintenance, centrifugal pumps should operate satisfactorily for a long period of time. Centrifugal pumps use the centrifugal force principal of accelerating the liquid within a rotating . Pump suction and discharge nozzles .All single stage pumps are provided with a double suction type impeller. The i-HT split case pump comes with externally removable type bearing housing, DIN cavity mechanical seal, impeller nut & sleeve arrangement and easy wear ring fitment. . Kirloskar i-HT axially split case centrifugal pumps are available in both single stage and double .

A double-suction centrifugal pump with tangential discharge volute (M1) and specific speed (n s) 19 has been selected for the numerical experiments. Transient analysis using detached eddy simulation is used for predicting flow parameter behavior at impeller periphery (primary source) and volute tongue locations (secondary source). The impeller . Pressure fluctuation is the primary factor that affects the stability of turbomachines. The goal of the present work is to explore the propagation of pressure fluctuations in a two-stage double-suction centrifugal pump. The pressure fluctuation characteristics of each component of a two-stage double-suction centrifugal pump are simulated under four typical flow rates based .

The main dimensions of impellers of double suction centrifugal pumps in this paper are shown in Fig. 2, which mainly consists of shroud, hub and blade (Fig. 3). The blade number is usually recommended between 5 and 7 for high head pumps. Six blades are chosen here. Too many blades which are related to higher friction losses may cause low blade .Xylem e-XC single stage, double suction centrifugal pumps come in so many models and materials that you can precisely configure your pump for your system. Simplify selection with pump materials, motors and seals based on your application. We’ll assemble your pump and get it on its way. Since the proper selection and configuration of your pump

7180 chemistry analyzer

Large Capacity, Single Stage, Double Suction Pumps designed for a Wide Variety of Industrial, Municipal, and Power Generation Services. Download Literature. Product Brochure; Installation Operation and Maintenance Manual (IOM) Specifications. Capacities to .

Double-suction centrifugal pumps have been applied extensively in many areas, and the significance of pressure fluctuations inside these pumps with large power is becoming increasingly important. In this study, a double-suction centrifugal pump with a high-demand for vibration and noise was redesigned by increasing the flow uniformity at the impeller discharge, .Xylem e-XC single stage, double suction centrifugal pumps come in so many models and materials that you can precisely configure your pump for your system. Simplify selection with pump materials, motors and seals based on your application. We’ll assemble your pump and get it on its way. Since the proper selection and configuration of your pumpIn double suction pumps, if directly connected elbows can not be avoided, they should be installed such that the elbows are in a plane perpendicular to the pump shaft. Figure 1 on the following page is an illustration of a single end-suction centrifugal pump piping arrangement typi-

Our Double Suction Centrifugal Pump is typically used in applications where large flow rates and high heads are required. With the pump body and impeller constructed from Stainless Steel, this pump, characterised by its unique design that allows for the simultaneous intake of liquid on both sides of the impeller, delivers a more balanced distribution of the liquid being pumped, a .

Actually, in this new configuration the vanes of a conventional back-to-back double suction centrifugal pump (chosen as a baseline) are substituted by an original vanes layout, which actually sees the vanes coming from either side of the double suction impeller alternately crossing each other at the outer diameter. It should be noted that some of the newer split case pumps do have improved casing inlet designs (less inlet turbulence), which allows them to approach the higher suction energy performance (gating values) of end suction pumps. 3. Double-suction pumps are more sensitive to the orientation and geometry (radius) of elbows in front of the pump .Bell & Gossett HSC Double Suction Centrifugal Pump Replacement Parts List; Designed and manufactured by the global leader in hydronic pump technology, the new Series e-HSC double suction pump provides engineers, contractors, and building owners a more powerful, serviceable, and efficient solution for a wide range of critical HVAC applications. .

The starting phase for pumps in water transportation pipelines is crucial and has significant transient characteristics which merit further study in order to evaluate the operational stability of the pumping system. This paper presents the results of a study in which the relative steady operating conditions and starting period of a large double-suction centrifugal pump . Double-suction pump is a special type of centrifugal pump, which is different from traditional single-suction pumps in that it has two suction ports located on both sides of the pump body. This design allows the double suction pump to suck fluid from two directions simultaneously, increasing its ability to handle high flow and high pressure .< View all Split Case & Double Suction Pumps. Xylem e-XC Single Stage, Double Suction Centrifugal Pumps Configure This Product. Related Products. Aquavar IPC Variable Speed Controller. Multistage ring section pump e-MP Multistage Pump. optimyze® Condition Monitoring. Find Products .

As an important type of centrifugal pump, the double-suction pump has been widely used due to its high efficiency region and large flow rate. In the present study, the complex flow in volute of a double-suction centrifugal pump is investigated by numerical simulation using a re-normalization group (RNG) k-ε model with experimental validation. Axial flows are observed .

The structure of a double-suction pump is more complex than that of a single-stage centrifugal pump and usually has a semi-spiral-type suction casing. To gain a comprehensive understanding of the energy dissipation of a double-suction pump, analysing the energy loss of its various components is necessary.The Azcue LD is a split casing pump, which is essentially a single stage centrifugal pump with a double suction impeller supported between bearings, splitting the pump case into two separate chambers.This double suction centrifugal design means that the LD is capable of much higher flow rates at lower pressures than alternative vertical centrifugal pumps, making them suitable .

Double Suction Centrifugal Pumps . 2 300 200 140 100 50 30 20 10 5 3 . new Series e-HSC double suction pump provides engineers, contractors, and building owners a more powerful, serviceable, and efficient solution for a wide range of critical . This study's research on wear ring clearance provides a reference for the design and application of double-suction centrifugal pumps. Topics. Computer simulation, Computational fluid dynamics, Turbulence theory and modelling, Fluid flows, Turbulent flows. REFERENCES. 1. V. K. Arun Shankar, S. Umashankar, S.

The double-suction centrifugal pump has gained extensive application in various hydraulic projects and industrial processes under direct and reverse operating conditions. However, the occurrence of unstable flow phenomena, such as flow separation, vortex and reflux, poses a significant challenge to its hydraulic performance. . Double-suction centrifugal pumps are generally designed for clear water, but the Yellow River contains a high amount of silt particles. When operating in sand-laden water, the pump impeller is usually eroded severely by silt, which leads to a decrease in pump performance and an increase in maintenance costs and downtime, and affects the .

what is double suction pump

For instance, the impeller diameter of a double-suction centrifugal pump in Huinanzhuang pumping station in China reaches 1.75 m, and its single installation power is 7500 kW . The internal flow in a double-suction centrifugal pump is extremely complex, especially under off-design operating conditions . Erosion wear in double-suction centrifugal pump is a critical problem for the JYRIP, which must be investigated to reduce erosion damage and improve the operating efficiency of the pumps. In this study, the sediment particle size distribution, shape and mineral composition were studied. The morphologies of the impeller surfaces after running .

mindray ba 88a semi-auto biochemistry analyzer

single suction vs double pump

single suction vs double impeller

Job costing provides a precise understanding of the costs associated with each job or project. This allows businesses to calculate the true cost of production and accurately price their products or services.

double-suction centrifugal pump|double entry centrifugal pump